The GST Story: The Past, Present, and Future of Logistics Management with Technology

Logistics optimization in India is not just a task, it’s a mission. People have been yearning for it since ages. Some have spent their life trying to make a broken system work. Initially, while setting up LogiNext, our core intent of logistics optimization through technological breakthroughs hit one of its biggest challenge as the optimization core in developing nations revolved around multiple tax loops. I never knew that along with having the best technology, we needed, perhaps, the best-chartered accountants. But we made it work. It’s about solutioning and we derive our energy from it.

But now it has happened. All for one, one for all. Standardized Goods and Services Tax (GST).

Before we begin, we must accept a fact. It’s not perfect. Not many things are in their Version 1.0. But it’s movement in the right direction. If the initial indications are anything to go by, the future holds bright for logistics management.

Let’s break it down in terms of time; past, present, and future; so, we can better understand the transformation that industries can expect.

The Past: Traditional Logistics Movement Across the Nation

One of the biggest challenges in logistics traditionally has been resource management. Resources include delivery personnel, vehicles, and drivers. Tracking and managing the multiple vehicles interlinking across multiple warehouses in different states was a big task before technology came to the rescue.

We solved this issue for them by establishing, for the first time in India, the viability of geofencing and location analytics.

Geofencing is when strategic locational metrics, such as latitudes and longitudes are tagged in a way that creates automated alerts and status updates for anyone tracking the vehicle’s movement.

Geofences are like virtual checkpoints. These checkpoints eliminated the visibility issue as companies now could track their shipments in real-time without depending on connecting with the driver one-on-one. Automation at the level of movement tracking came as a welcome boost for these enterprises.

Using real-time tracking and predictive traffic analytics, estimated from historical movement information, we could give the accurate estimated time of arrivals (ETAs) to all the stakeholders, including the source hub, incumbent hubs, and the destination hub; the warehouse or retailer. Each stage of the delivery was keenly supplied with regular detention alerts which helped them manage their hub load around resource ability for loading and unloading purposes. They could align their processes around the ETAs, avoiding any unnecessary downtime.

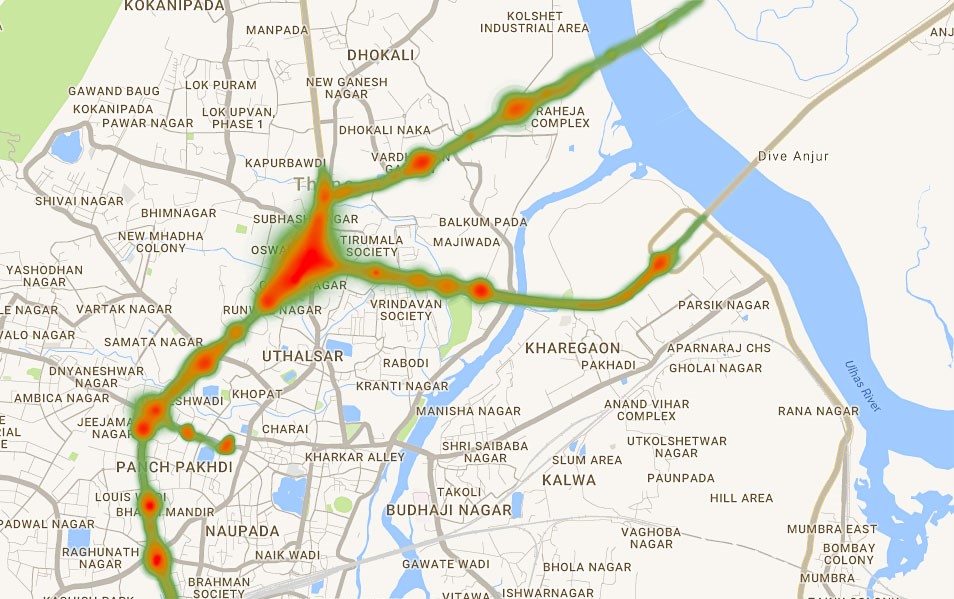

Before GST: Detention Time, Heat Map

Even with extensive geo-fencing and delivery route optimization, the vehicles had a high detention time of about 36 hours per trip, solely due to multiple intra-state octroi and toll check posts. This was a huge bottleneck in terms of optimization as it was uncontrollable detention. Even aligning possible detention times within the ETAs, the accuracy around the same went down by 10-15%. For a company taking pride in their accuracy, it was a bitter pill to swallow. So, we didn’t. We bettered our location analytics, increasing the accuracy of our real-time tracking, in-turn increasing the reaction time imparted to the subsequent stakeholders. This helped the stakeholders to compensate for the detentions. We compensated for one functional problem but were still stuck on another.

As the tax amount varied across states, clients used to plan their logistics through a broken and fragmented model, decreasing the amount of goods traversing borders at any given time to reduce taxes. But this led to less than full truckloads moving across the country, accumulating a loss of optimal utilization. Another major problem was that the routes were set, not to optimize time, but to reduce taxes. To save money, optimization was put to trial, as the routes selected were not the best ones, but with the least taxes. These things put a constraint on the incentive to optimize amongst clients.

The Present: At the Cusp of Development

To put the standardized tax plan in perspective, we must consider the impact an ideal optimization system. In such an ideal system, the following would be the immediate and pronounced benefits:

- 30% increase in operational efficiency/productivity

- 50% increase in resource utilization

- 20% decrease in fuel costs and other overheads

- 70% increase in service level agreement (SLA) fulfillment

- 60% increase in efficiency from third-party logistics partners

- 20% decrease in overall turnaround time (TAT)

- 25% decrease in overall logistics cost

These ideal metrics are formulized based on the assumption that the current bottlenecks that are holding back these potential benefits would be unleashed once these bottlenecks are removed.

GST has come as a transforming agent for multiple industries. Taking out the multiple taxations, the government has essentially fixed three major gaps.

1. State Level Taxation for Logistics Movement: Detention time increased primarily because of this reason. Each such tolling booth recorded close to an hour of detention. Across the nation, trips moved through multiple states, and each entry-exit point compounded the detention. This detention could be predicted with partial accuracy as the traffic and frequency patterns were situational. The clients worked around benchmarks, which in themselves, were 15-20% error rate. Even a few hours offshoot of an ETA could throw a wrench in the functionality of other hub processes.

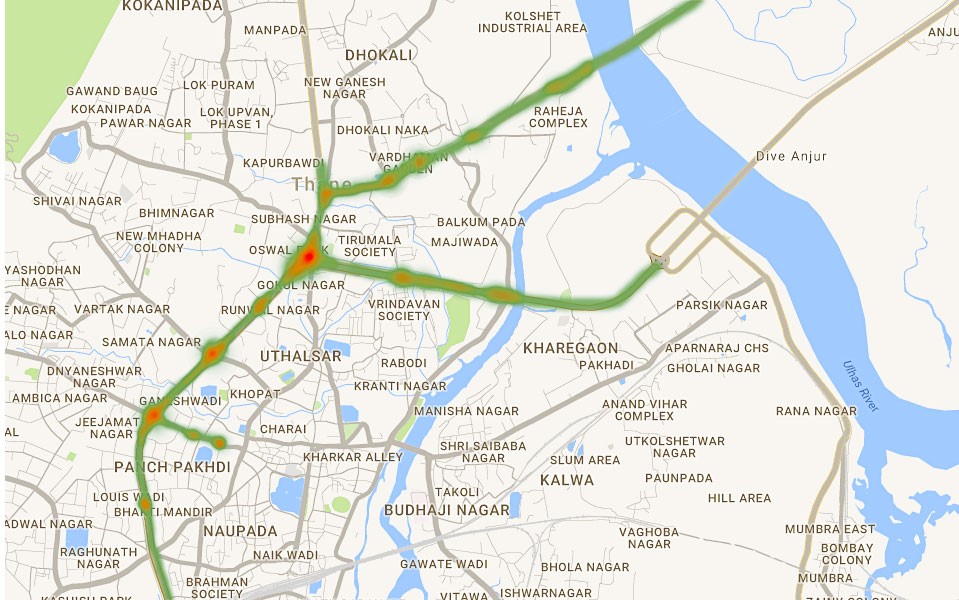

Solution: With tolling booths going out of service, detention time at checkpoints has come down drastically. Clients now have much more confidence on the accuracy of their prescribed ETAs, increasing the compliance rate of different SLAs.

2. Differing Level of Taxation from One State to Another: This possibly was the greatest problem of all. Differing level of taxation created a negative incentive to move away from resource and route optimization. Clients chose to set up hubs in states which contributed to a reduction in overall taxation. This was at the expense of proper optimization, sometimes resulting in longer routes and overcapacity resources.

Solution: With the negative incentives out of the picture, companies are now free to re-plan their logistics movement networks around the proper hub-and-spoke model, and not the previously used small pocket hubs. The new model, which many companies have invested in now, revolves around mega-distribution centers.

3. Decentralized Tax Collection Points: Decentralized collection of taxation resulted in invoicing and accounting hassles around proper logistics cost management. A significant amount of time and money was lost in understanding and filling of multiple taxes across states.

Solution: With centralization of tax collection, companies can now bring visibility and accountability in their billing and invoicing. Such accountability would bring better control over budgets, and more secure quarterly investment and development plans for logistics.

Amongst all this, our report card after GST’s implementation shows that LogiNext is not far-off the ideal marks.

- Operational efficiency/productivity: 24% increase

- Resource utilization: 47% increase

- Fuel costs and other overheads: 16% decrease

- Service level agreement (SLA) fulfillment: 67% increase

- Efficiency from third-party logistics partners: 54% increase

- Decrease in overall turnaround time (TAT): 16% decrease

- Decrease in overall logistics cost: 22% decrease

After GST: Detention Time, Heat Map

The Future: Revolutionizing Optimization through Technology

We now stand at the forefront of the optimization revolution. Never has sweeping transformational changes benefited multiple industries more than right now. GST holds the promise of total realignment and restructuring of how logistics movement happens across the nation. There would some resistance from some companies, as many are set in the way they have been doing things over a period and are averse to any sudden change. This is where technology must play its part to convince enterprises to the potential returns on these actions.

Our technological expertise, at LogiNext, has given us the valued position of guiding confused enterprises to the better parts of the current transformations. We have aligned machine learning with our location analytics utilizing a combination of MongoDB database platforms with elastic searching capabilities to incorporate our billion data points to optimize the routes and planning possibilities of our multiple clientele. Data points are locational identifiers, each holding unique latitude and longitudes. The data points run through a progressive machine learning engine which adds and correlates various data points to create a virtual mapping network holding historical information about traffic, weather, and other details pertaining to geographical areas divided across territories and postal codes.

This virtual network, our very own neural network, has given us the rare functionality of predictive analytics.

Predictive analytics, as the name suggests, is when companies can predict the potential or probable opportunities or bottlenecks arising from their routes before they happen. This gives them the foresight to plan their resources and logistics movement accordingly and be prepared for all variances. Predictive bottleneck identification has obvious applications as in having the planning engine function in a way that it can predict traffic and other variables, increasing the chances of on-time deliveries. The opportunities, here, are more exciting. Clients can analyze logistics movement frequency across geographies and plan their future logistics network development around these areas.

As of now, there are seven major customer hubs around the country. With the Mihan Project running successfully out of Nagpur, such multi-modal logistics hubs can be set up across Mumbai, New Delhi, Ahmedabad, Bangalore, Hyderabad, and Kolkata. These distribution networks would satisfy the demand-supply model covering most of Tier-2 and Tier-3 cities. This would eventually increase the truckloads, incentivizing full-truck loads, and possibly the fabled uberization of freight forwarding. Logistics management industry would not just consolidate towards positive profit realizations, but also build on itself to absorb growing demands emanating from e-commerce and retail.

The realignment of the national distribution networks would help in directing traffic movement across capable national highways, avoiding mismanaged interior roadways.

And with the government opening infrastructure to 100% Foreign Direct Investment, the channels for optimization would just keep on growing.

The future seems brighter than ever before. We must now reach out and make it a reality.

226 2

Pingback: LogiNext-Blog | Alok Gautam, Country Logistics Leader, Dow Chemicals, in Conversation with LogiNext

Pingback: LogiNext-Blog | Alok Gautam, Country Logistics Leader – India, Dow Chemicals, in Conversation with LogiNext