5 Ways Automated Distribution Centers for Perishable Products Are the Future in Logistics

In the rapidly evolving world of logistics, efficiency and speed are more important than ever. Retail giants like Walmart are pioneering new ways to manage the supply chain, particularly for perishable goods that require quick and careful handling. One groundbreaking innovation is the development of automated distribution centers for perishable products. These high-tech facilities use cutting-edge technology and logistics management software to streamline processes, reduce waste, and ensure fresh items reach consumers in the best possible condition. Today, let’s explore five key ways these automated distribution centers for perishable products are shaping the future of logistics.

What Are Automated Distribution Centers for Perishable Products?

Automated distribution centers for perishable products are state-of-the-art facilities designed to handle items with short shelf lives. These centers use advanced technology and intelligent software to manage storage, sorting, and distribution efficiently. The goal is to ensure that perishable items like fruits, vegetables, dairy, and meat reach store shelves quickly and in optimal condition.

Quick Read: Pop-Up Warehousing and its Use Case

Why Are Automated Distribution Centers Important?

Automated distribution centers for perishable products are crucial because they address the unique challenges of managing perishable goods. Traditional distribution methods can be slow and labor-intensive, often resulting in spoilage and waste. Automated centers reduce these risks by speeding up processes and maintaining ideal storage conditions. This efficiency is vital for retailers aiming to minimize losses and maximize freshness for consumers.

How Do Automated Distribution Centers Work?

Automated distribution centers for perishable products operate using a combination of robotics, AI, and temperature-controlled environments. Automated systems handle the movement of products within the facility, from unloading trucks to sorting and storing items. Advanced logistics management software tracks inventory in real-time, ensuring accurate stock levels and efficient order fulfillment. The use of automation reduces the need for manual labor, making the process faster and more reliable.

Discover: How can Delivery Management Software Avoid Food Recall?

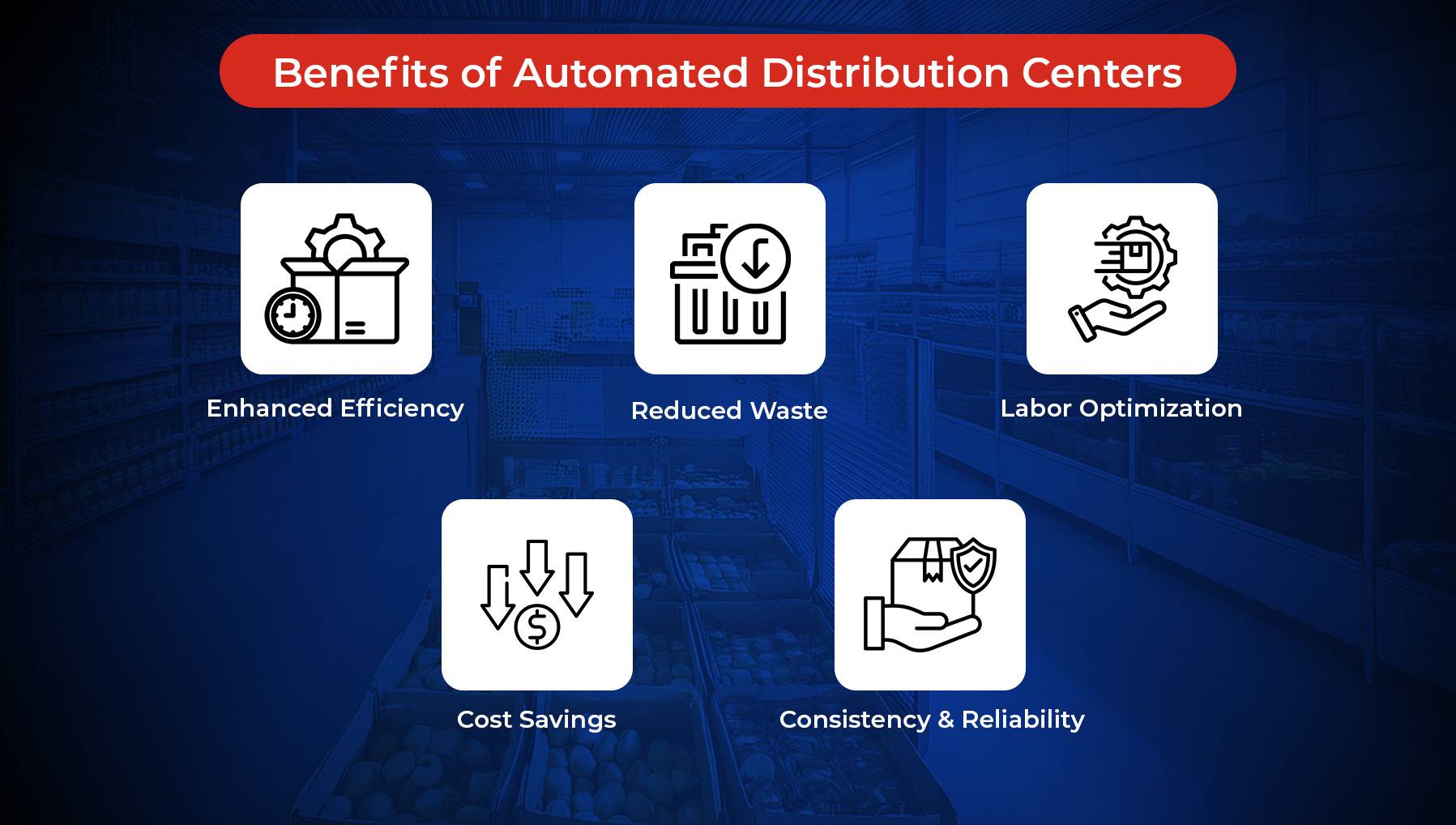

What Are the Benefits of Automated Distribution Centers?

Enhanced Efficiency

Automated distribution centers for perishable products process items at a much faster rate than traditional centers. These facilities can handle thousands of items per hour, significantly reducing the time it takes for goods to move from the warehouse to store shelves. For example, some automated systems can sort up to 24,000 items per hour, compared to the 6,000 items per hour typical in manual systems. This speed is crucial in ensuring that perishable goods like fruits, vegetables, and dairy products reach consumers while still fresh.

Reduced Waste

Maintaining optimal storage conditions and accelerating the distribution process are key to reducing spoilage and waste of perishable goods. Automated distribution centers for perishable products use advanced temperature control systems to keep items fresh, minimizing the risk of spoilage. According to the Food and Agriculture Organization (FAO), approximately 14% of the world’s food is lost between harvest and retail. By improving the efficiency and conditions of the supply chain, automated centers can help reduce this percentage significantly.

Labor Optimization

Automation allows workers to transition from physically demanding tasks to roles that involve overseeing and maintaining high-tech systems. This shift not only reduces the risk of workplace injuries but also often comes with better pay. For instance, Walmart by automating its distribution centers is expected to create around 2,000 new jobs, with many positions offering higher wages compared to traditional roles. Employees can focus on managing and optimizing automated processes, leading to a more skilled and satisfied workforce.

Cost Savings

Improved efficiency and reduced waste translate to lower operational costs for retailers. By processing items faster and reducing spoilage, automated distribution centers for perishable products help retailers save on labor and waste management expenses. These savings can then be passed on to consumers through lower prices. A study by McKinsey & Company estimates that automation in distribution centers can reduce operating costs by up to 20%, providing a significant competitive advantage.

Consistency and Reliability

Logistics management software ensures a consistent and reliable process, minimizing human errors and enhancing overall supply chain reliability. Automated systems can track and manage inventory in real-time, providing accurate data on stock levels and product locations. This level of precision reduces the likelihood of stockouts or overstocking, which are common issues in traditional distribution centers. Logistics management software ensures that the supply chain operates smoothly, even during peak demand periods.

Read More: Streamline Warehouse to Delivery Operations with TMS

By embracing these innovations, retailers can not only enhance their operational efficiency but also improve customer satisfaction through better product availability and freshness. As distribution centers for perishable products continue to automate, they represent a key component of the future of logistics, driving growth and sustainability in the industry.

Conclusion

Automated distribution centers for perishable products are transforming the logistics landscape. By leveraging advanced technology and logistics management software like LogiNext, these facilities address the unique challenges of managing perishable goods, offering numerous benefits including enhanced efficiency, reduced waste, and labor optimization. As retailers like Walmart continue to invest in these high-tech centers, the future of logistics looks increasingly automated, efficient, and sustainable. Embracing this innovation is essential for staying competitive in the fast-paced retail environment. Book a demo with LogiNext to experience the future in logistics.

94

@LogiNext