Supercharge Your Supply Chain by Mastering 3PL Partnership

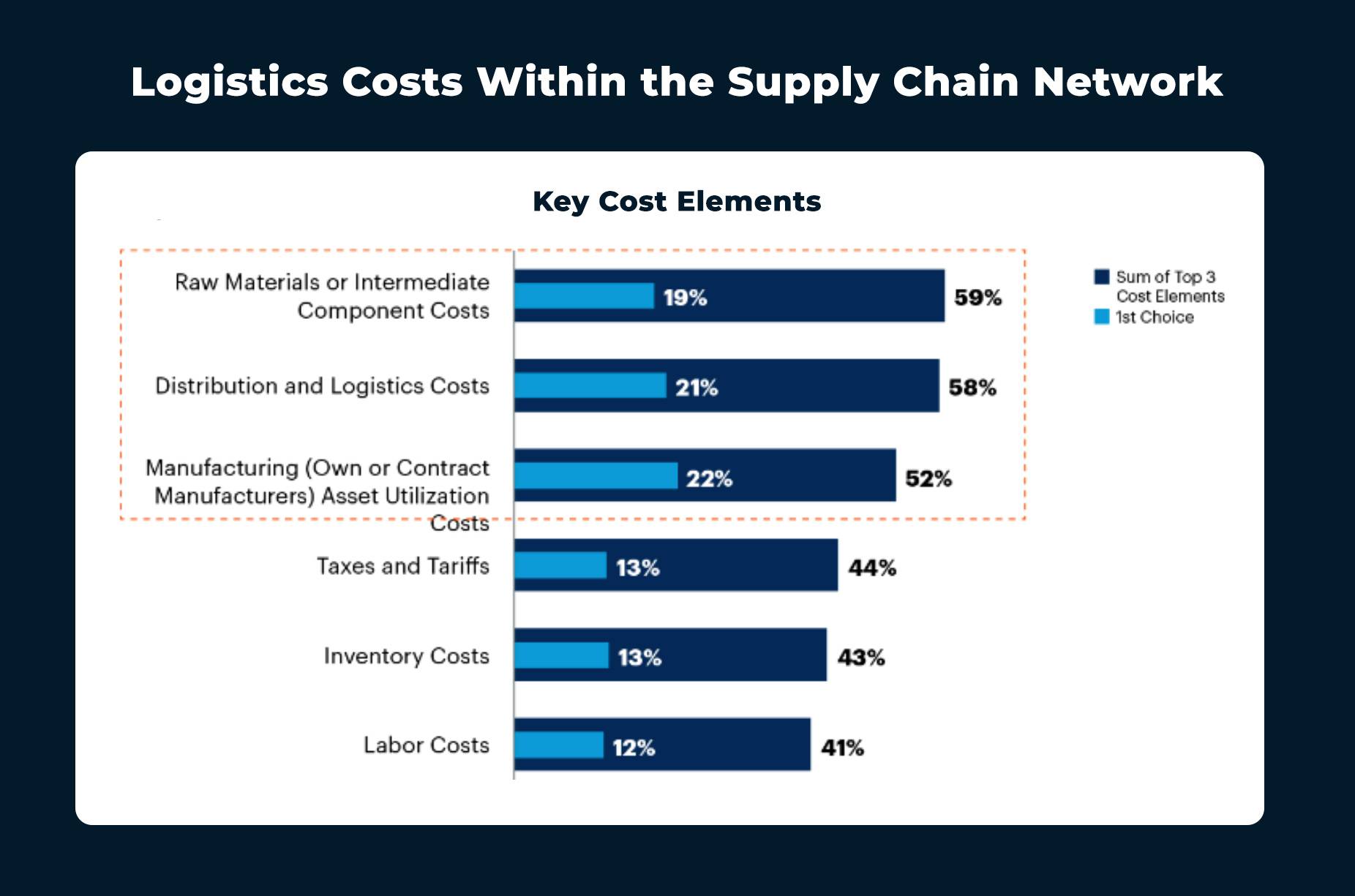

Nowadays, organizations are pressured to reduce logistics costs. To meet this demand, there has been a surge to explore new 3PL partnerships with lower costs. Here, the need for 3PLs who are reliable and offer flexible contracts has become the need for the hour. As per Gartner, the utilization of own-fleet assets contributed to the top 3 costs estimated in the supply chain.

As the world gets back to normalcy, which is helped by reduced costs and available capacity. However, it would be wise to stick with current 3PL partners to avoid unwanted risks associated when hiring a new 3PL logistics partner. By tweaking contracts and working closely together, companies and their 3PL partners can save money and still keep things running smoothly.

However, it’s important to note not all logistics markets can be treated the same. For instance, the European Market is still reeling from Russia’s invasion of Ukraine. The Red Sea Crisis is another example of disruptions in the supply chain. Logistics companies still face labor shortages and higher shipping costs. Hence it becomes crucial that your organization knows what to look for and sets clear expectations, to get a good deal.

The approach followed by logistics leaders to optimize transactional costs

The global 3PL logistics providers come with multiple trade lanes that they operate in – Airways, Roadways, Waterways, and Railways. The demand for each industry section varies as per customer’s demands and needs. Therefore, adequate benchmarking is needed to negotiate optimal pricing at the critical negotiation stage with 3PLs. But what are the key pointers to observe?

1. Set clear expectations and measurement criteria for 3PL performance, ensuring they provide regular data for evaluation.

2. Utilize the Hierarchy of Logistics Metrics to establish a comprehensive performance framework.

3. Regularly assess metrics in supplier meetings and quarterly reviews to track ongoing performance.

4. Address challenges collaboratively, embracing change to enhance 3PL performance.

5. Implement reward programs tied to metrics, offering incentives for improved performance and fostering long-term partnerships.

Don’t miss out: The Ultimate Guide To Master 3PL Logistics

How to negotiate contracts and rate agreements with 3PLs?

When partnering with 3PL providers, logistics leaders should explore the risks and flexibilities offered during the relationship’s life cycle. To maintain consistency and avoid costly changes, one should adopt strategies to contain costs, provide flexibility, and promote collaborative partnerships.

Reducing 3PL Cost:

Understanding the cost factors within the 3PL’s control is valuable. This flexibility allows for negotiation on various expenses like customs and transportation.

Many 3PL charges, such as fuel and customs fees, are industry-driven. Tracking these costs helps establish fair market rates.

Ensure costs are reviewed at set intervals with supporting evidence, as outlined in the contract terms.

Collaboration aids the 3PL in network management. Top-notch logistics programs ensure predictability and cost advantages.

Offering 3PL Flexibility:

Navigating the complexities of forecasting capacity requirements with third-party logistics (3PLs) using historical shipping and demand data presents a challenge, particularly in volatile market conditions. The inherent unpredictability in market dynamics often results in inaccuracies in demand forecasting, leading to unexpected spikes in demand that can significantly impact capacity planning with carriers. These fluctuations inevitably translate into increased logistics costs for businesses.

To mitigate the risks associated with uncertain demand forecasts, logistics leaders need to adopt a proactive approach during contract negotiations with their 3PL partners. One effective strategy is to build flexibility into contractual agreements, allowing for greater adaptability and cost control while ensuring service reliability.

Rather than solely relying on the open market for capacity allocation, establishing prearranged contracts with existing 3PL partners can offer several advantages. By leveraging the established relationship and mutual understanding, businesses can negotiate terms that provide flexibility in capacity allocation, enabling them to adjust to changing demand patterns more efficiently.

An ideal contract structure should accommodate fluctuations in demand by offering seasonal, monthly, or weekly flexibility in capacity commitments. This ensures that businesses can scale their logistics operations according to evolving requirements without incurring unnecessary expenses during periods of low demand or facing capacity constraints during peak seasons.

Additionally, incorporating a fixed priority fee above the negotiated base rate, while remaining competitive compared to spot market rates, enhances cost predictability for both parties. This approach balances cost control and service quality, offering convenience, consistency, and competitiveness in the logistics partnership.

Offering Incentives for 3PL Improvements

Ensure continuous improvement (CI) isn’t just a vague term in your contract. Direct your 3PL’s account team towards CI initiatives. These initiatives should be rewarded and measured for industry relevance, service enhancements, and technological innovations. This ensures ongoing value and cost improvements throughout the contract duration. Make CI programs integral to your master service agreement, with clear quantitative metrics. Regularly review and follow up on these programs within your supplier relationship management framework.

5 steps followed by organizations to meet cost-saving targets using 3PL

Logistics leaders typically set annual cost reduction targets aligned with corporate objectives. However, meeting these goals can be challenging due to fluctuating logistics factors like supply and demand, market dynamics, labor, and fuel costs. Consequently, logistics teams must continually develop and implement initiatives to surpass targets and achieve planned objectives.

1. Implement targeted cost-saving measures with realistic timelines for sustainable improvements.

2. Foster lasting behavioral changes to prevent cost increases and maintain long-term efficiency gains.

3. Promote innovation and continuous improvement to drive organizational growth and development in logistics.

4. Optimize key roles and responsibilities to mitigate risks and ensure seamless operations.

5. Strategically negotiate shipping contracts to leverage technologies and services for favorable terms and cost-effective solutions.

Also Read: Why Does Your Delivery Management Tech Platform Need A Solid Integration Marketplace?

How can LogiNext help with cost savings for 3PL logistics?

LogiNext can assist with cost savings for 3PL logistics through several key features and functionalities:

Route Optimization: LogiNext’s route optimization algorithms help streamline delivery routes, reducing the distance traveled, fuel consumption, and associated costs.

Real-Time Tracking: By providing real-time visibility into shipment status and driver locations, LogiNext enables better resource utilization and proactive decision-making to minimize delays and avoid additional costs.

Dynamic Scheduling: Our dynamic scheduling capabilities allow for agile adjustments to delivery schedules based on real-time changes in demand or operational constraints, optimizing resource allocation and reducing idle time.

Predictive Analytics: By utilizing predictive analytics to forecast demand, identify potential bottlenecks, and optimize resource allocation, helping to prevent costly delays and inefficiencies.

Performance Analytics: LogiNext offers comprehensive performance analytics and reporting tools to monitor key metrics, identify areas for improvement, and optimize operational efficiency, ultimately driving cost savings.

Automation: By automating repetitive tasks such as order processing, invoicing, and documentation, reduces manual errors and administrative overhead, and leads to significant cost savings over time.

Load Consolidation: Our load consolidation capabilities allow 3PL providers to optimize truckload utilization by combining multiple shipments, reducing transportation costs per unit, and minimizing empty miles.

Compliance Management: LogiNext helps 3PL providers stay compliant with industry regulations and customer requirements, avoiding costly penalties and fines associated with non-compliance.

Carrier Integration: We facilitate seamless collaboration with 3PL partners, enabling efficient communication, coordination, and resource sharing, which can lead to cost savings through economies of scale and improved efficiency.

Customer Experience: By enhancing visibility, transparency, and communication throughout the delivery process, LogiNext helps 3PL providers deliver superior customer experiences, leading to increased customer satisfaction, loyalty, and repeat business, ultimately driving down customer acquisition costs.

Conclusion

LogiNext offers a comprehensive suite of features and capabilities designed to help 3PL providers optimize their operations, reduce costs, and deliver superior value to their customers. While managing 3PL partnerships, it’s all about communication, flexibility, and finding ways to save money without sacrificing quality. If you can do that, you’ll be sailing smoothly through the supply chain world in no time! To know more, click on the red button below.

91

@LogiNext